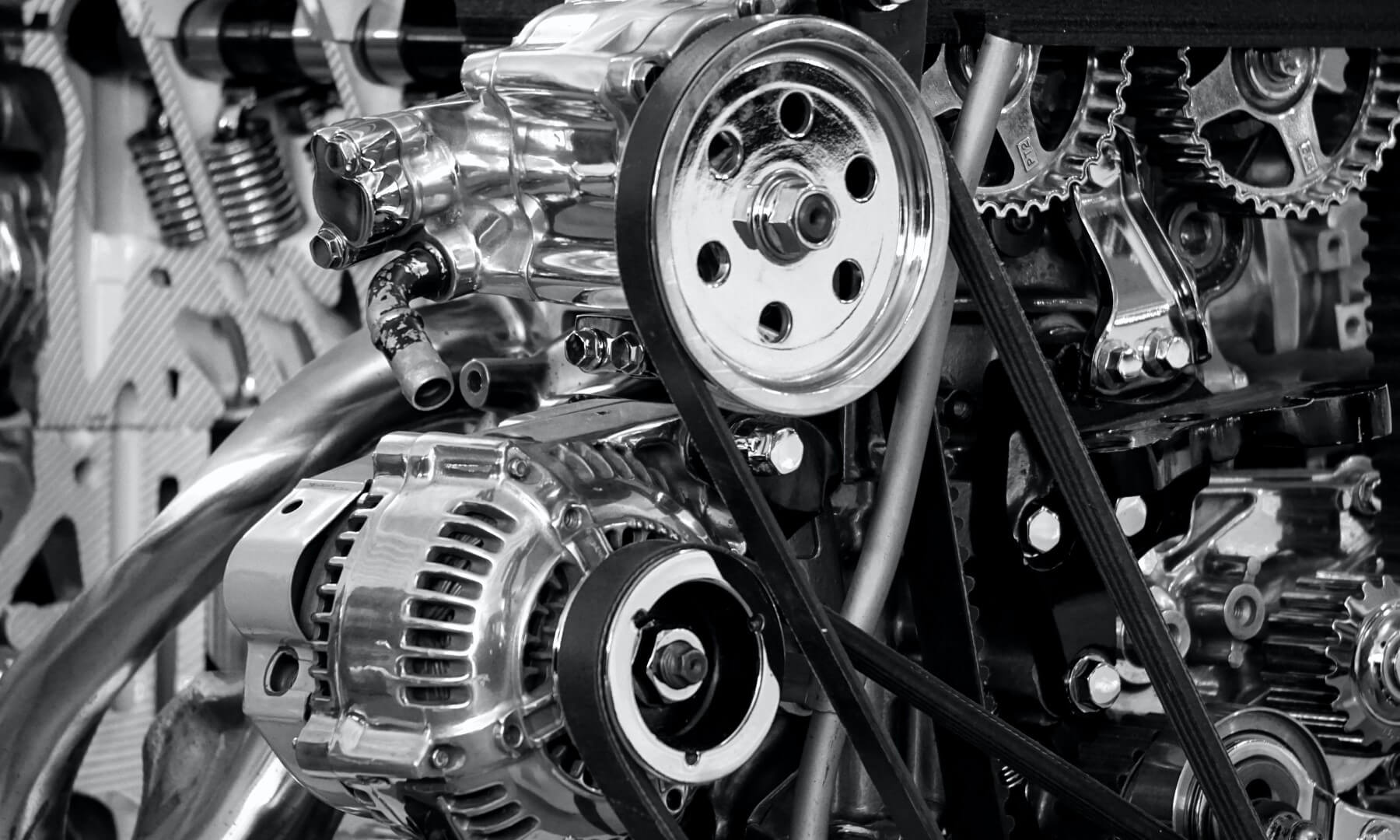

When building or modifying an engine, paying attention to the small details, including the fasteners, is essential. Engine fasteners are the nuts, bolts, and studs that hold the engine together. They play a crucial role in ensuring everything stays in place. Using the right fasteners can help prevent issues like leaks, vibrations, and even engine failure.

There are many different types of fasteners that are used in engines, including bolts, studs, and nuts. These fasteners come in a variety of sizes and materials, each designed to handle specific loads and stresses. Some common materials used for engine fasteners include stainless steel, titanium, and chrome-moly. It’s essential to choose the right fasteners for your engine build to ensure that they can handle the loads and stresses that your engine will be subject to.

Types of Engine Fasteners

When it comes to engine fasteners, there are three main types to consider: bolts, nuts, and washers, and studs. Each type is crucial in keeping your engine together and running smoothly.

Bolts

Bolts are externally threaded fasteners designed for insertion through holes in assembled parts. They come in a variety of shapes and sizes. These include hex and 12-point heads, and are used for a range of applications, from cylinder head bolts to intake manifold bolts to header bolts.

One of the most important bolts to consider are head bolts, which are responsible for securing the cylinder head to the engine block. Rod bolts and connecting rod bolts are also crucial. These hold the connecting rod to the crankshaft and the piston to the connecting rod, respectively.

Washers and Nuts

Nuts and washers are often used in conjunction with bolts to provide a secure and stable connection. Nuts are internally threaded fasteners that screw onto bolts. Washers are thin, flat discs that sit between the head of the bolt and the surface it is being tightened against.

Stainless steel nuts and washers are ideal for many automotive and marine applications because stainless is tolerant of heat and virtually impervious to rust and corrosion.

Studs

Studs are threaded rods that are inserted into a threaded hole and then secured with a nut. They are often used in applications where a bolt may not be able to provide the necessary strength, such as main studs which secure the main bearing caps to the engine block.

ARP studs are a popular choice for high-performance engines, as they are made from high-strength materials and are designed to withstand extreme forces.

Overall, it is important to choose the right type of fastener for your engine to ensure a successful build. Whether you are using bolts, nuts and washers, or studs, make sure to select the appropriate size, material, and strength for your specific application.

Understanding Fastener Mechanics

When it comes to engine fasteners, understanding the mechanics behind them is crucial for ensuring proper installation and preventing engine failure. In this section, we’ll cover the basics of fastener mechanics, including clamping force, bolt stretch, and preload.

Clamping Force

Clamping force is the force that holds two mating surfaces together. It’s created when a fastener is tightened, causing it to stretch and compress the materials it’s holding together. The amount of clamping force depends on several factors, including the size and material of the fastener, the thread pitch, and the torque applied during installation.

Bolt Stretch

Bolt stretch is the amount of elongation a fastener experiences when it’s tightened. As a fastener is tightened, it stretches and compresses the materials it’s holding together, creating clamping force. The amount of bolt stretch is directly related to the clamping force created. Measuring bolt stretch is important for ensuring that the proper amount of clamping force has been achieved during installation.

Preload

Preload is the force applied to a fastener before it’s tightened. It’s created by stretching the fastener to a specific length before installation. Preloading a fastener helps to ensure that it will maintain the proper clamping force over time, even as the materials it’s holding together expand and contract due to temperature changes.

It’s important to use a stretch gauge during installation to achieve the proper preload. This tool measures the amount of elongation a fastener experiences when it’s preloaded, allowing you to adjust the preload as needed to achieve the desired clamping force.

Overall, understanding fastener mechanics is key to ensuring proper installation and preventing engine failure. By paying attention to factors like clamping force, bolt stretch, and preload, you can ensure that your engine fasteners are performing their job correctly and keeping your engine running smoothly.

Engine Fasteners in Performance Applications

Regarding high-performance applications, engine fasteners play a crucial role in ensuring that the engine can withstand the increased power output and stresses that come with it. In this section, we’ll take a closer look at the importance of high-performance fasteners and the types of fasteners that are commonly used in specific engines.

High-Performance Fasteners

High-performance engines require high-quality fasteners that can withstand the increased stress and vibration of high RPMs and boost. These fasteners are typically made from stronger materials such as titanium or high-grade steel. Materials that are designed to handle higher loads and stresses than their standard counterparts.

When selecting high-performance fasteners, it’s important to choose ones that are specifically designed for your application. For example, if you have a big block Chevy engine, you’ll want to look for fasteners designed to handle this engine’s increased power output. Similarly, if you have a Ford or Pontiac engine, you’ll want to look for fasteners designed to work with these specific engines.

Check out some racing inspired apparel by clicking through to our online shop.

Fasteners for Specific Engines

Different engines require different fasteners, depending on their design and power output. For example, engines with high compression ratios require head bolts that can handle the increased pressure, while engines with high power output require rod bolts that can handle the increased load.

When selecting fasteners for your specific engine, it’s important to choose ones designed to work with your engine’s specific requirements. This may include factors such as the engine’s compression ratio, power output, and intended use.

One option to consider is an engine fastener kit, which includes all of the necessary fasteners for your specific engine. These kits are designed to ensure that you have all of the fasteners you need to assemble your engine properly. They can help to ensure that your engine can withstand the increased stresses and loads that come with high-performance applications.

Overall, when it comes to engine fasteners in performance applications, it’s important to choose high-quality fasteners. Fasteners that are designed to handle the increased stresses and loads that come with high RPMs and boost. By selecting the right fasteners for your specific engine, you can help to ensure that your engine can perform at its best and withstand the increased stresses that come with high-performance applications.

Engine Fasteners and Safety

When it comes to your engine, safety should always be a top priority. Engine fasteners are crucial in keeping your engine components intact and functioning properly. In this section, we will discuss the importance of engine fasteners in ensuring the safety of your engine.

One of the main reasons engine fasteners are so necessary is because they prevent the failure of critical engine components. If an engine fastener fails, it can cause a domino effect that can lead to catastrophic engine failure. This is why it’s essential to use high-quality, properly rated fasteners that are designed to withstand the stresses of your engine.

Another important characteristic of engine fasteners is their resistance to rust and corrosion. Rust can weaken the structural integrity of a fastener, making it more prone to failure. This is why it’s crucial to use fasteners that are made from materials that are resistant to rust and corrosion, such as stainless steel.

In addition to using high-quality fasteners, it’s also important to properly torque them to the manufacturer’s specifications. Over-tightening or under-tightening fasteners can cause them to fail prematurely, leading to engine damage or failure.

Finally, it’s essential to regularly inspect your engine fasteners for signs of wear or damage. If you notice any issues, such as rust or stripped threads, it’s important to replace the fastener immediately to prevent further damage.

In summary, engine fasteners play a critical role in ensuring the safety and reliability of your engine. By using high-quality fasteners, properly torquing them, and regularly inspecting them for signs of wear or damage, you can help prevent engine failure and keep your engine running smoothly for years to come.

Conclusion

In conclusion, engine fasteners are an essential component of any engine. They play a crucial role in ensuring that all engine parts are securely held together, preventing any unwanted movements or vibrations that could lead to engine damage.

When selecting fasteners for your engine, it is important to consider the specific application and requirements. The shape and quality of threads on a bolt or stud are essential. They should be created using a lathe and then hardened to improve their mechanical strength.

Proper installation and tightening of fasteners are critical to ensure optimal engine performance and prevent potential safety hazards. Always follow the manufacturer’s specifications for torque and tightening sequence.

It is also important to note that fasteners are not a one-size-fits-all solution. Different engines and applications require different fasteners, such as bolts, nuts, and washers. Choosing the right type and size of fastener is crucial to ensure optimal performance and longevity of your engine.

Overall, engine fasteners may seem like a small component of an engine. But they play a critical role in ensuring optimal performance and safety. By selecting the right fasteners and following proper installation and tightening procedures, you can ensure that your engine runs smoothly and reliably for years to come.

![Ferrari Vision Gran Turismo Debuts [w/video]](https://doubleapex.co.za/wp-content/uploads/2022/11/Ferrari-Vision-Gran-Turismo-500x383.jpg)

![Forza Horizon 5: Driving Is LIIIIIFFFEEEE [video]](https://doubleapex.co.za/wp-content/uploads/2021/11/Forza-Horizon-5-trailer-500x383.png)

Leave A Comment