Double Apex was recently invited to attend an international summit hosted by Chery Group in China. Part of that trip included a Chery factory tour. We share just some of what we learned about the brand during our time in the East.

Chery is a name that grows more familiar in the automotive arena with each passing week. The Chinese brand has experienced exponential growth in the local context since reintroduction into the SA market in 2021. From 98 units in its first month of operating locally, it now boasts well over 1 000 new vehicles sold in any given month. If you don’t believe us, just take a look at the monthly new-car sales figures (as reported by NAAMSA), where Chery is a regular top-ten runner.

Follow Double Apex on Instagram and Facebook where we share more car content.

Stepping Up

Of course, our err… more ‘seasoned’ readers may recall the Chery products from about a decade ago. Some of the earlier offerings were less than stellar. However, recent, first-hand, experience of the brand’s portfolio have shown a quantum leap over those older products.

Chery is now comparable to similar vehicles from more mainstream and established automakers. On a recent visit to Chery’s HQ in the town of Wuhu (what a great name), we got to see exactly why this is the case.

All In-house

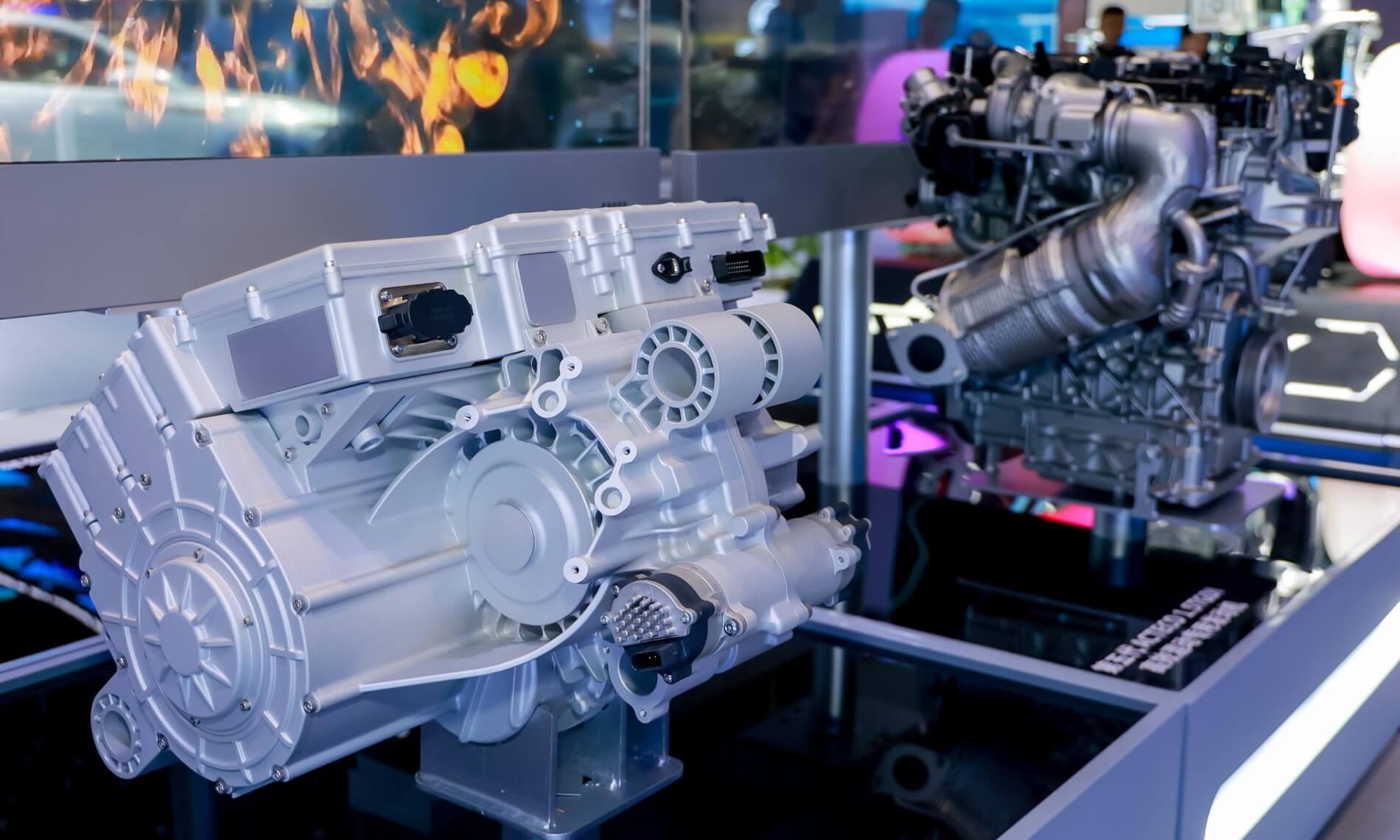

Chery has a world-class manufacturing facility, as modern and advanced as just about any other current plant we’ve had the good fortune to visit. The factory covers an area of 550 000 m². This includes a stamping workshop, welding workshop, painting facility, general assembly areas, engine and transmission workshops. The production process has an accuracy of up to 0,1 mm, which is right up (down?) there with the best in the world.

There are also innovations that we have not yet seen in other car plants. Delivery of parts by fully autonomous robots is one such example. The other is a variable height floor platform beneath each vehicle. This allows the unibody to be raised and lowered during the assembly process, depending on the action carried out at that workstation.

All of this allows for the simultaneous production of regular power and new energy passenger vehicles. A brand-new complete vehicle rolls off the production line every minute. Incidentally, the production process has been designed to be energy efficient with the aim of being a zero emission ‘green’ factory.

R&D Across The Globe

We also got to pop in for a brief visit to Chery’s R&D facility in Wuhu. It is one of five facilities based in four countries around the globe including China, Germany, the USA and Brazil.

The R&D facility includes NVH facilities, kinematics and compliance testing, an anechoic chamber and crash-test labs. Such facilities allow the firm to produce its own platforms, engines, transmissions and, importantly in the modern era, battery and EV tech. Tests and experimentation carried out here has helped gain Chery five-star ratings in five different NCAP programmes. Incidentally, that feat is a first for any Chinese automaker.

Chery Group, the parent company, owns almost all parts of the automotive production process. From engines and platforms to electronics infrastructure, the company owns a subsidiary that produces the requisite parts. In fact, Chery even sells some of its own products (engines and infotainment systems as examples) to other automakers.

Future Models

Our travels to China also gave us an opportunity to experience and see Chery products that are not yet (and some that won’t be) available in South Africa. Among the models that are not coming to SA are sedans from the stable, but not necessarily wearing Chery badges.

There were also a few SUVs, some with fully connected functionality that showcase Chery’s parity with the likes of BMW and Mercedes-Benz in the connected car stakes.

We also got to try out a few models that ARE coming to SA. These included the Omoda C5 AWD, Jaecoo J7 (more info to follow in a subsequent article) and a large luxury SUV that was recently launched in the domestic market, but not yet committed to a nameplate when it arrives in SA.

Our drive experiences were brief, and confined to the parking area of a theme park. However, the fundamentals we’ve come to learn about the brand are all there. Each car features plenty of tech, high-res displays, loads of standard kit and plush ride quality. We didn’t get out of second gear during our test drives, but the engines across the Chery range tend to overlap quite a bit so they aren’t unknown quantities.

Summary

We spent a lot of time in the presence of Chery staff and dealers from the SA market. The positivity towards the brand is palpable and it’s not difficult to see why.

There is an ever-increasing portfolio of products, with the SA line-up tailored to current buying trends in our market (read: SUV/crossover heavy). With what we saw during the Chery factory tour it’s not difficult to see why the company is on the up and up, both in SA and across the world.

![[UPDATED] Mazzei Formula Five Is One Man’s Obsession](https://doubleapex.co.za/wp-content/uploads/2024/08/Mazzei-Formula-Five-500x383.jpg)

![Ferrari Amalfi Introduced as Roma’s Replacement [w/video]](https://doubleapex.co.za/wp-content/uploads/2025/07/Ferrari-Amalfi-500x383.webp)

![Koenigsegg Sadair’s Spear is a Limited-Edition Track Weapon [w/video]](https://doubleapex.co.za/wp-content/uploads/2025/07/Koenigsegg-Sadairs-Spear-rear-500x383.webp)

Leave A Comment