A tough start

When the 2016 race season started, I wasn’t sure we’d even make it to the opening round. However, with the help of excellent sponsors and suppliers who worked tirelessly to prepare the car, we did.

In fact, despite a few tight deadlines we contested every round of the Fine Cars series that runs as part of the regional Power Series championship. Constant accumulation of points is the reason I managed to bag third place overall.

Special thanks

Apart from the backing of key sponsors, which have all been outlined in earlier updates, the team at GT Graphics deserves special mention. Not only does the sign-writing and design firm store my car but the petrolheaded team that works there is also responsible for the upkeep and maintenance of the car between races, for which I am eternally grateful.

Looking ahead

With a successful season of racing under our belts it’s already time to look ahead to 2017. Project MX-5 will be competing in the same category next year. With more experience in the series we’ll be looking for better results, more points, perhaps a few more wins to add to the single victory last year, and ideally a better championship position come year end.

Racecar preparation

As any good race team will tell you, success comes from what you do before the season as much as it does from what you do in the season. With that credo in mind we’ve already started to prep Project MX-5 for 2017. If you followed the updates (if not there are links below) then you will know we’ve carried out a few mechanical updates (ECU, radiator, inlet system), but the one area we’ve not touched is the braking system.

Factory stock

MX-5s of all generations have four-way disc brakes as standard. In my very early model, the discs measure 235 mm up front and 231 mm at the rear. While these have been adequate they are a tad smaller than is ideal in a race application.

Research revealed that the later, 1,8-litre models came with 254 and 251 mm discs. So we started to look around for replacement items. A quick call to Pretoria-based braking specialists Powerbrakeresulted in a pair of 254 mm jobbies from their GT range of discs.

These uprated items have been developed for the rigours of track use increased resistance to distortion over regular discs, as well as improved heat transfer properties to aid with heat dissipation. The GT discs’ slot pattern design improves initial bite and aid in pad outgassing as well as keeping the pad surface de-glazed.

Powerbrake offer them in standard size for replacement of OEM items for a multitude of models. With the fronts in hand we bought a set of new off-the-shelf rears. Thankfully the only change needed to adapt to the large brake disc is a larger caliper cradle. The caliper itself is the same on the 1,6- and 1,8-litre cars. MX-5 owner and adept technician Andre du Plessis generously donated his caliper carriers to the cause.

Pads from afar

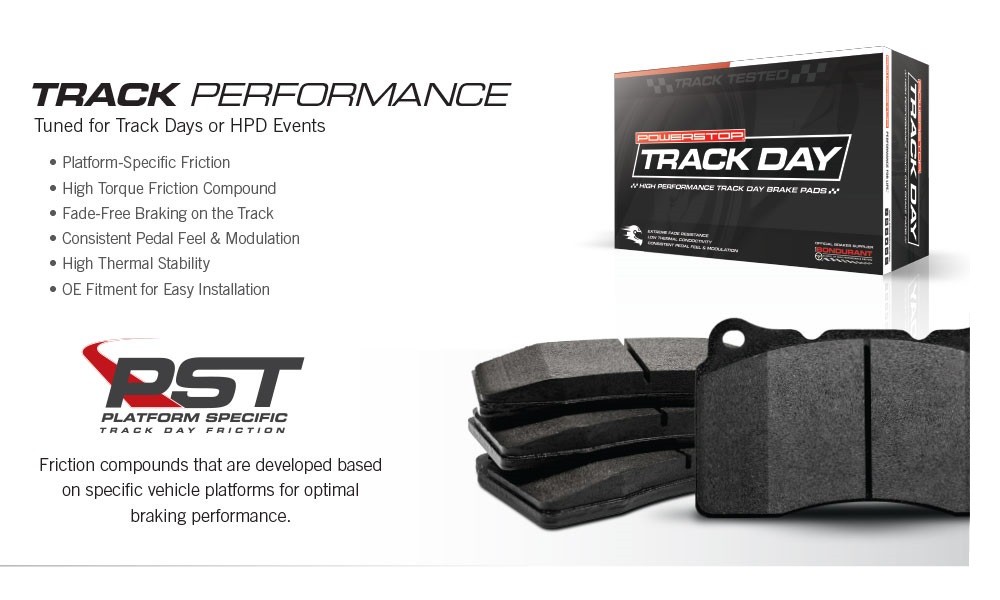

Kristopher Miller is an American car enthusiast who has been following the adventures of Project MX-5 since he first saw a link to one of the stories many months ago. Fortuitously, Miller also happens to work for a Chicago-based firm called Power Stop. You can probably guess what they do…

After hearing that we were still using standard brakes, Miller offered us a set of Power Stop’s Track Day Brakes. These are constructed from a carbon-fibre metallic compound that promises better performance and longer life.

A quick swap

With all the pieces in hand, it was a simple matter of swapping the cradles between my car and Du Plessis’ as well as fitting the replacement discs and pads. Spanner-twirler Du Plessis made good on his promise and took just a few hours to complete the entire job.

While we were at it we replaced the brake fluid with Motul RBF, which was kindly sent over by the chaps at Powerbrake.

Rigorous bedding procedure

Unlike everything I’ve ever been told about bedding in new brake pads, the Power Stop pads come with a rigorous procedure (see pic above for more). This was carried out as per instruction, though it is a bit hair-raising hitting the brake pedal that hard with a fresh set of pads on cold semi-slicks.

We’re really keen to find out how much of a difference the uprated brakes make to the lap time, and we’ll be making a trip to Killarney Raceway soon to find out.

Reader feedback

As usual, all comments and suggestions are welcome. I look forward to hearing from you. For intermediate updates feel free to follow the Project MX-5 facebook page.

![Rally Raid MX-5 [video]](https://doubleapex.co.za/wp-content/uploads/Rally-Raid-MX-5-front-2-500x383.jpg)

Leave A Comment